Traceability

Production batch traceability

ContactOperations - Traceability

The computerisation of all production phases at FPT - Fonderia Pressofusione Tapparo enables the rapid and safe traceability of production lots at each stage of the process, from initial order to delivery to your warehouses.

Request a consultation

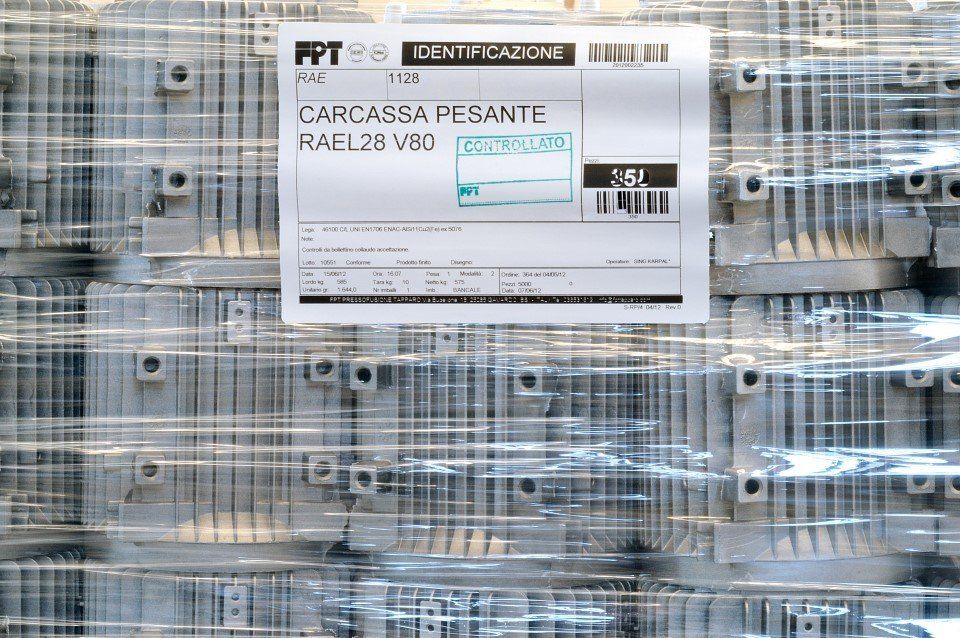

Each package has a personalised identification tag created with proprietary software that can be fully adapted to your needs, showing the image of the piece and bar code, to meet the logistical needs of tracking die-casting components.

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Processing phase traceability

The identification of each package is guaranteed by a proprietary computer system, which recognises every detail through the bar code. The QR code printed on the label also allows you to read and store all the information contained on the slip on your mobile phone.

- Read more

Design office and production departments, technologically equipped warehouses, organisational culture and the ability to integrate with your operations ensure the best product performance, personalised service, maximum efficiency and extremely competitive costs for the production of aluminium, zamak and special alloy die castings.

Our information system is integrated with yours through the use of exchange files and systems such as barcodes and QR codes.

For information about the traceability of die-casting components, fill in our contact form.

Discover traceabilityVia Budellone, 18 - 25085 Gavardo BS, Italia

+39 0365 31619

Thanks for contacting us. We will get back to you as soon as possible.

An error occurred while sending the message. Please try again later.

OFFICE

Via Budellone 18, 25085 Gavardo (BS)

CONTACT DETAILS

+39 0365 31619